Pump-probe sampling

Rapid and precise thin-film inspection.

Introduction

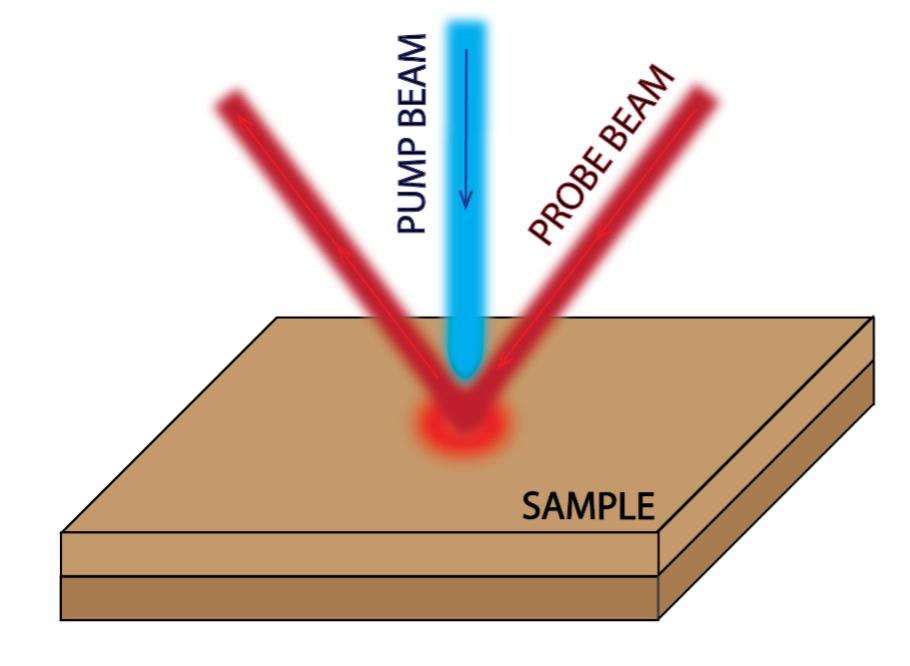

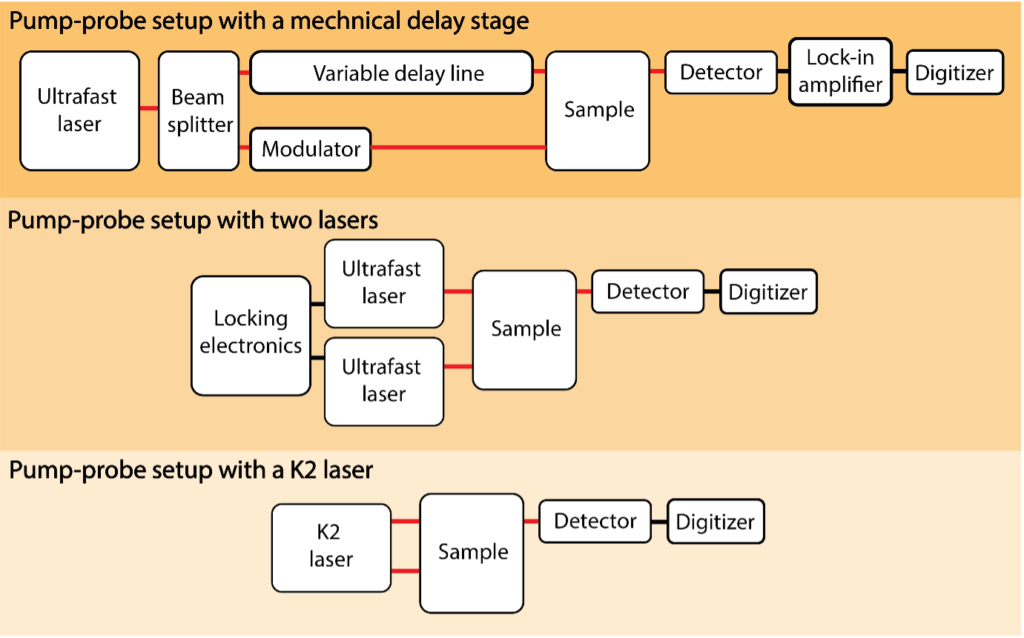

Pump-probe sampling is a powerful technique used to observe ultrafast processes (fs to ns) in materials and biological systems. It involves shining a brief, intense pulse of laser light onto a sample (the “pump” pulse), which excites the sample and initiates a physical process or reaction. A time-delayed second pulse of laser light (the “probe” pulse) is sent through the sample to measure changes in its optical properties that occurred because of the initial excitation. By varying the delay between the pump and probe pulses, a detailed temporal record of the sample’s response to the pump pulse with high temporal resolution is obtained.

The key challenge: optical delay scan

Rapid optical delay sweeps without moving parts: two laser approach

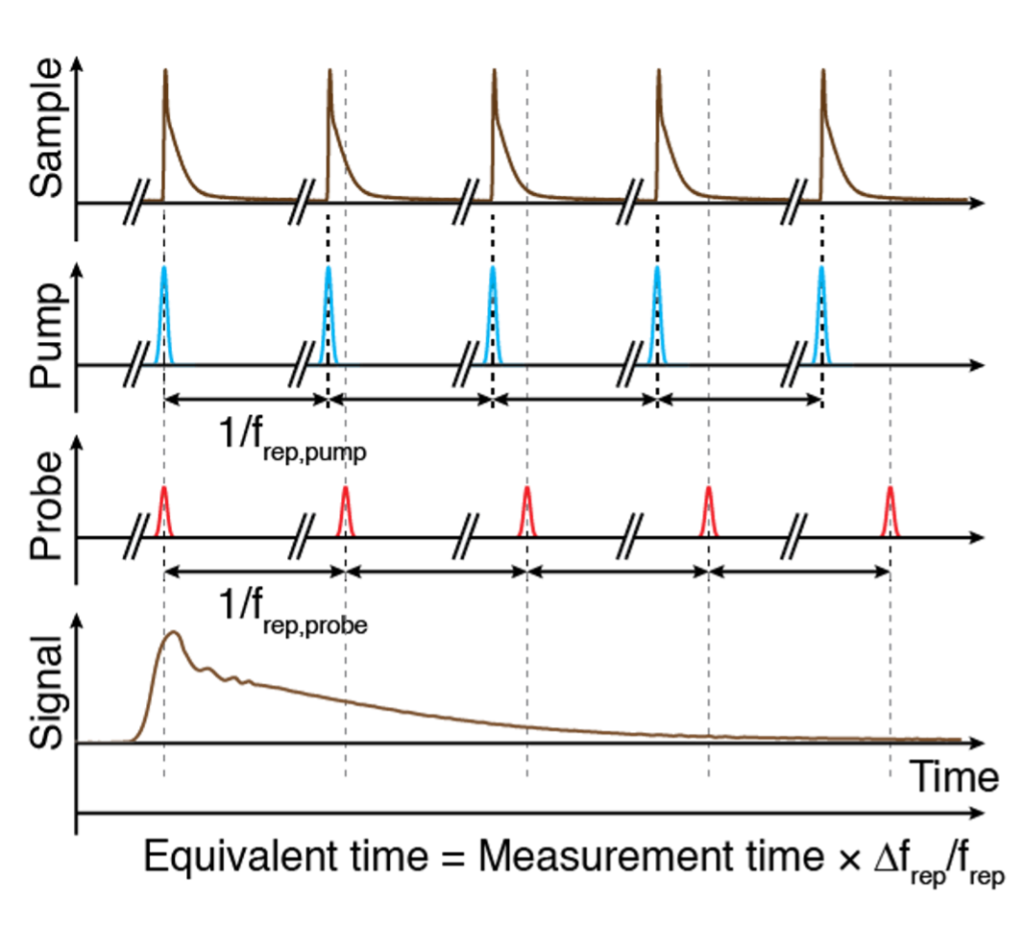

ASOPS is an alternative method to obtain long optical delay scans in pump-probe measurements. It uses two different optical pulse rates, one for the pump and one for the probe, which allows for precise and fast scanning of the optical delay between them. This technique is commonly used in ultrafast photoacoustic and other transient absorption studies. The range of the scan is determined by the pump repetition rate, and the scan speed is determined by the difference between the pump and probe repetition rates.

| Parameter | Variable |

| Pump repetition rate | ƒrep,pump |

| Probe repetition rate | ƒrep,probe |

| Repetition rate difference | Δƒrep = | ƒrep,pump — ƒrep,probe | |

| Delay scan range | 1 / ƒrep,pump |

| Delay sweep time | 1 / Δƒrep |

| Delay scan step | τ ≈ Δƒrep / ƒrep2 |

| Measurement bandwidth | BW, typically, up to ƒrep / 2 |

| Time step resolution | τ ≈ Δƒrep / (ƒrepBW) |

Rapid optical delay sweeps without moving parts: single laser approach

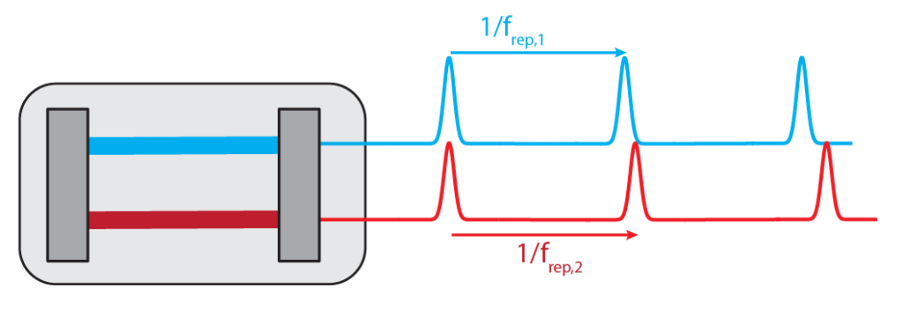

K2 Photonics has developed a unique solution for ASOPS that uses a single laser to achieve optical delay scans without the need for two separate ultrafast lasers. This is achieved by generating two pulse trains within a single laser cavity, each of which can be used as the pump and probe source, respectively.

This single-cavity dual-comb laser solution provides several advantages over traditional two-laser ASOPS systems. Firstly, it greatly simplifies the experimental setup, reducing the number of components required and leading to a more compact and stable system. Secondly, it enables improved time axis stability as both pump and probe sources are generated from the same laser cavity and thus have correlated pulse noise characteristics. This suppresses the need for electronic feedback loops between two separate lasers and greatly improves the overall stability of the system.

Shot-noise limited signal detection capability

K2 Photonics has opted for solid-state laser technology to create their single-cavity dual-comb laser system. This technology enables laser light with an ultra-low intensity noise at high frequencies. Typically, the relative intensity noise (RIN) is below -160 dBc/Hz for frequencies above 1 MHz. This low noise floor is especially advantageous for ASOPS, as most of the signal of interest lies at high frequencies that are not affected by the laser noise. In fact, the noise on the signal is mainly originating from the shot noise of the probe detecting photodiode, which is determined only by the probe power and responsivity of the photodiode. As a result, the use of solid-state laser technology in the K2 Photonics system results in a higher signal-to-noise ratio ASOPS measurement with a perfectly linear time delay axis, making it a more sensitive tool for ultrafast spectroscopy and other applications.

K2 Photonics value proposition for pump-probe applications

Various pump-probe study examples with our technology are showcased in the Resources section.